Automatic Case Packer, TP-C20

Automatic case / cardboard box / carton box packing machine for tissue / toilet roll / handkerchief paper

TP-C20 automatic case packing machine is perfect for packaging a variety of individually wrapped or multi-pack wrapped tissue products, such as soft facial tissues, paper hand towels, paper serviettes, V-fold napkins, N-fold napkins, etc.

10 cartons/min

Output

20kW

Total power

Length: 95-210mm

Width: 90-100mm

Height: 50-80mm

Width: 90-100mm

Height: 50-80mm

Dimension of Individually Wrapped Tissue:

Packaging Style

Specifications

| Application | To pack individually wrapped or multi- pack wrapped tissue products into carton box |

| Feeding mode | Automatic 5-lane intelligent feeding |

| Max. feeding speed | 240 packs/min |

| Dimension of individually wrapped tissue | Length: 95-210mm Width: 90-100mm Height: 50-80mm |

| Package configuration | 16, 18, 20, 24, 27, 30, 36 packs/carton |

| Design speed | ≤12 carton/min (depending on product size) |

| Working speed | ≤12 carton/min (depending on product size) |

| Carton type | 3/5 ply corrugated board, 5mm thickness, required to be preformed with folding line |

| Carton storage | ≤100 cartons |

| Carton sealing | Adhesive tape |

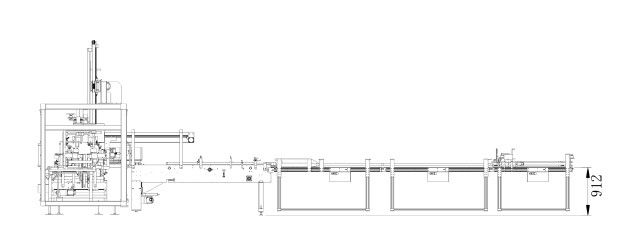

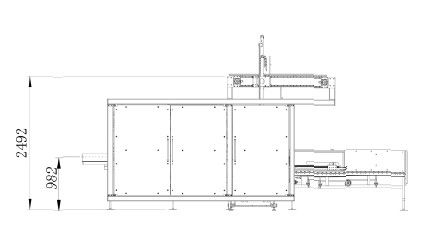

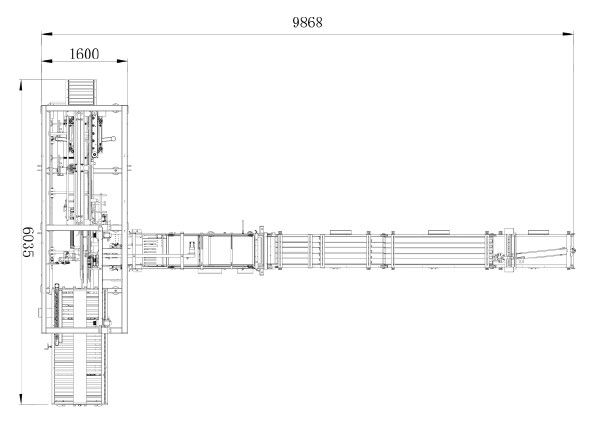

| Machine dimension | 9768mm×6030 mm×2400mm |

| Machine weight | 4000kg |

| Compressed air | ≥0.6MPa (prepared by user) |

| Power supply | 380V/50Hz |

| Motion control | Servo/inverter/cylinder positioning control |

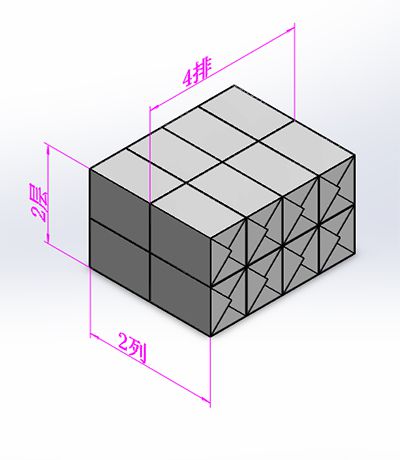

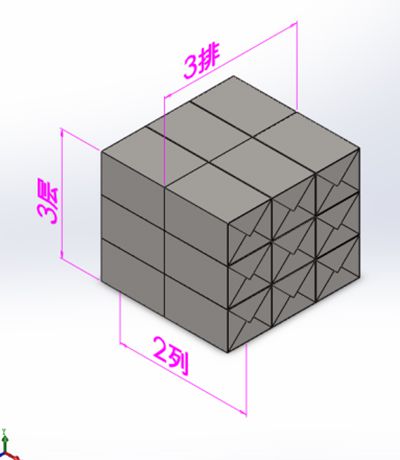

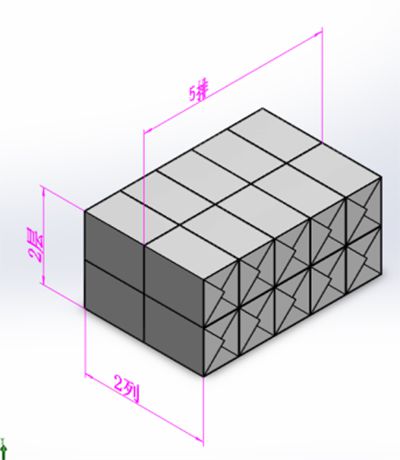

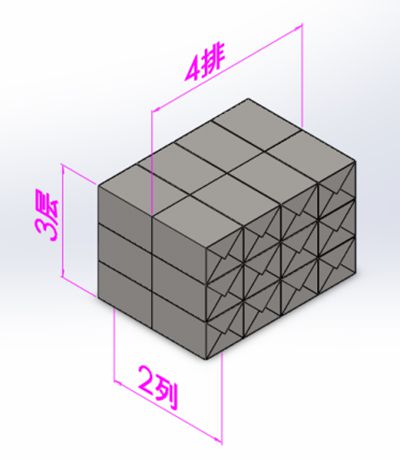

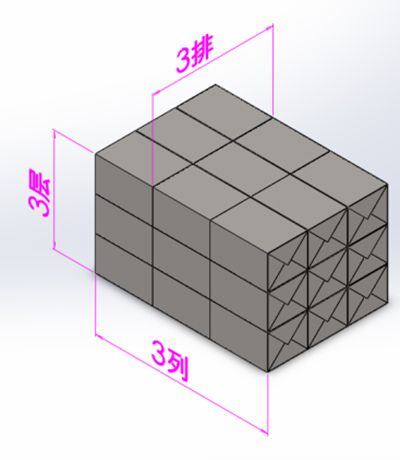

Package configurations are available as follows

16 packs

16 packs  18 packs

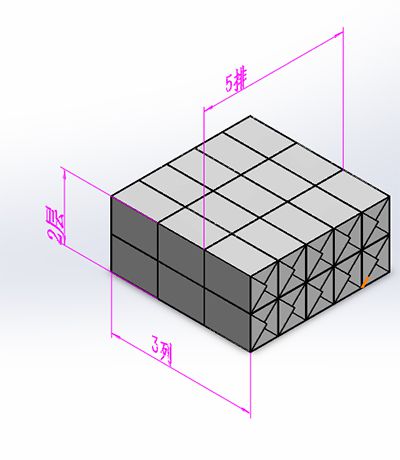

18 packs  20 packs

20 packs  24 packs

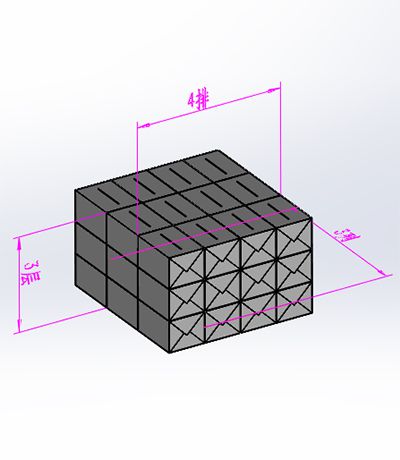

24 packs  27 packs

27 packs  30 packs

30 packs  36 packs

36 packs Features

- Using servo drive to control lane dividing, tissue stacking & inserting, carton erecting and sealing, providing easy operation and simple maintenance;

- Adopting FESTO pneumatic parts and MITSUBISHI electrical parts, ensuring high precision and stable operation;

- HMI interface with touch screen, easy to operate;

- Automatic fault diagnosis and identification, allowing to quickly locate the fault and show it on the display, significantly facilitating the equipment maintenance;

- Monitor system automatically detects whether there is shortage of packaging bags or lack of products;

- Automatic case sealing with adhesive tapes, ensuring tight and secure seals while providing superior look;

- Feeding system is designed with servo lane dividing unit, can meet the needs for packing of various specifications;

- Equipped with functions of air source management, fault alarm and display, servo overload protection

Diagram

IMAKO is a company entirely focused on the manufacture of automated making and packaging equipment for tissue industry. We always aim at developing user-oriented innovative solutions for worldwide tissue paper convertors to solve their tissue paper production & packaging and toilet paper packaging needs. To become a global advanced machine manufacturer, we also develop optimal packaging solutions for personal care products apart from tissue converting industry. All of our tissue making and packaging machines and hygiene product packaging machines like baby diaper packaging machine, wet wipes packaging machine and sanitary pad packaging machine are built to deliver easy operation, high productivity, quick size changeover and simple maintenance. If you are still struggling to choose the right tissue making and packaging machine, we'll be happy to help you with your tissue production needs.